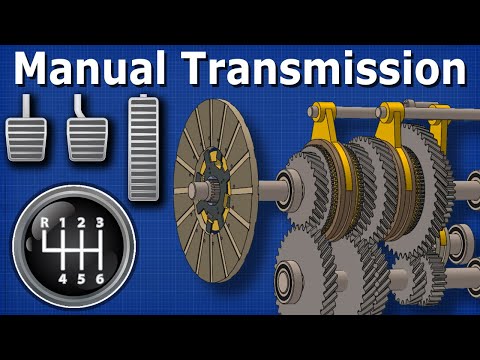

An automated guide gearbox is precisely what its name suggests, however you won’t find a clutch pedal and gearlever shifting themselves round as if by magic. In reality, in most cases the gear selector seems similar to a standard automatic’s, and there’s no clutch pedal at all. Inside a CVT gearbox you’ll find two cone-shaped pulleys – one connected to the engine and the other driving the wheels, linked by a belt.

These investments are primarily directed towards creating new merchandise and increasing distribution networks, which is able to, in flip, stimulate future demand. From 2024 to 2030, the Automotive Gears market is expected to experience regular and optimistic growth, suggesting a promising future for the trade. This progress is driven by a number of key factors, together with rising client demand, technological developments, and evolving consumer preferences.

It is a flat bar onto which the tooth of a pinion gear are engaged. These gears are designed to accommodate a wide variety of purposes. The enamel on helical gears are specially minimize at an angle, so as to face the gear. As two teeth on the gear system interact, it begins a contact on one finish of the tooth which steadily spreads with the gear rotation, until the time when both the tooth are fully engaged.

Manufacturing Of Spur Gears

The water gasoline response is essential within the control of the atmosphere carburizing course of. Instruments such as dew level analyzers monitor the H2O/H2 ratio of this equation while infrared (3-gas) analyzers and oxygen probes take a glance at the CO/CO2 ratio. In atmosphere carburizing parts are heated to austenitizing temperature in a “neutral” endothermic or nitrogen/methanol containing approximately forty percent hydrogen, 40 % nitrogen, and 20 p.c carbon monoxide.

Steel

For gear merchandise, induction hardening is effective for hardening tooth areas together with tooth surface and the tip, nonetheless, the basis will not be hardened in some cases. Generally, the precision of gears declines from deformation caused by induction hardening. For induction hardening of S45C products, please check with the values beneath. What’s more, because there aren’t any fixed gears, there are no gearchanges – and that means clean acceleration without any jolts. One cause why automobile makers are falling out of affection with handbook gearboxes is that they price so much to develop at a time when demand is diminishing. Modern vehicles, especially these with computerized transmissions, are heavily reliant on electronics for gear modifications.

It has been 35 years since Gears India entered the market and has been servicing the business ever since. It is possible to reduce the vary of stock items that are suitable solutions when sure high quality standards are a giant issue . A stock answer that meets the standard criteria and basic performance necessities could additionally be powerful to find. Restrictions apply to the availability of knowledge used in this paper. Data was obtained from an industrial companion and are available from the authors with the permission of the economic partner.

Heavy Automobile Vehicle Transmission Gear

Rotary broaching of splines, torx and hexes could be integrated in our CNC machining processes. International and regional electrical vehicle producers are leveraging new applied sciences to innovate and increase their services globally. A universal milling machine is used within the production of car gears for gear slicing, forming, and finishing. Figure 6.Precision and recall values for 306 images automotive gears of broken enamel defects. When tightening the constraints on the number of consecutive images and prediction confidence, from Figure 6, we anticipate the mannequin to additionally miss detecting some gears with a defect. Table three presents the false-negative prediction results, when applying our model and constraints on the check set of 30 defective gears (Section 5.2).

Faulty spark plugs, clogged gas injectors, or air consumption issues can hinder acceleration. Even in low gears, if the engine isn’t delivering adequate power, the car will wrestle to choose up speed. There can be a number of causes, similar to worn-out clutch plates, low transmission fluid, or a damaged gearbox, which intrude with the graceful transitioning between gears in your automotive. Starting with small enter and huge output pulleys allows the optimum engine and enter pulley rpm to turn the driven or output pulley much slower. Copolyester elastomers having moduli from 10,000 to 250,000 psi are used in lower-speed and lower-load gears. Grades with a Shore D hardness of 25 or 30 work nicely in two-shot molding to manage noise and dampen vibration.